Failure Prediction and Predictive Maintenance for Industrial Rotating Machines

Utilizing AI to proactively predict machinery failures, enabling the prevention of downtime and the planning of maintenance intervals. This approach enhances inventory management, reduces operational costs, and allows for higher availability guarantees.

Starting Point

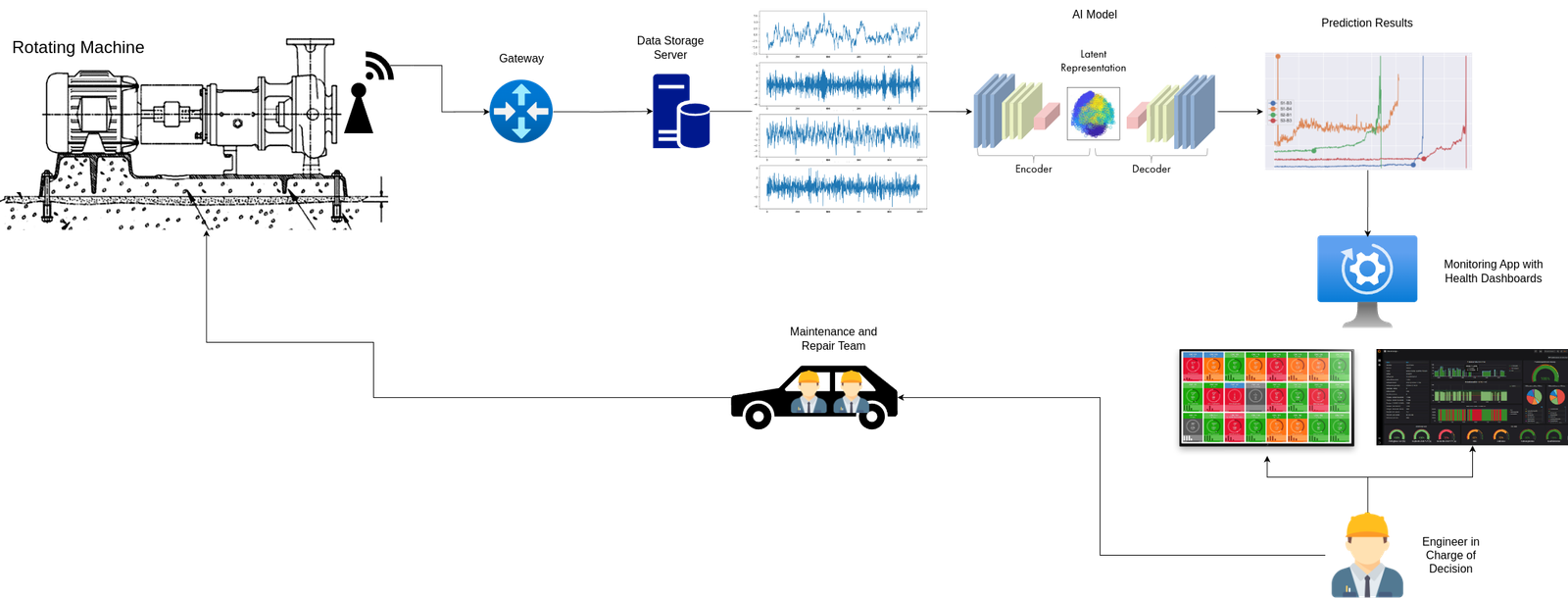

IoT sensors, externally mounted on machines, gather key telemetry data including vibrations, rotational speed, and temperature. This data is collected, aggregated, and periodically transmitted to an analytics server where it undergoes AI-driven analysis.

Objective

The objective of the AI models is to evaluate the machine's status using incoming telemetry data. Should a degradation in machine state be detected, the model aims to predict the lead time to failure and offer an estimation of the potential type of failure.

Added Value

Our predictive model forecasted machine failures with a lead time of 20 to 42 hours, enabling the engineering team to take corrective actions and prevent machine downtime. By deploying this solution across more than 2000 machines, we significantly reduced operational costs and achieved an ROI within 11 months.

From Challenges to Solutions

The Downtime of Industry Machines is Expensive

Industrial applications such as manufacturing processes, power generation, and cooling systems depend crucially on the continuous operation of machinery. Downtime in these sectors is not only disruptive but also incurs substantial financial losses due to halted production and operational delays. To manage these risks, Service Level Agreements (SLAs) are established, requiring machinery suppliers to guarantee specific levels of machine availability.

Challenges of Maintenance and Operational Costs

The lack of real-time insights into the health status of deployed industrial machinery presents a challenge for effectively scheduling maintenance intervals. This issue is particularly critical for machines with strict availability requirements, where maintenance must be performed at frequent intervals to mitigate the risk of breaking SLAs. Additionally, on-call service protocols are established to ensure rapid response to failures. Both practices lead to high operational costs.

Balancing Cost and Efficiency in Inventory Management

To ensure on-demand repair or replacement of defective machinery, a robust and efficient inventory management system is important. Companies frequently maintain an overprovisioned stock to guarantee immediate availability for repairs and replacements, especially when obligated by SLAs that require prompt action. While this strategy enables compliance with SLAs, it also increases the operational costs associated with maintaining the inventory.

Predicting Failures ahead of Time by Detecting early Symptoms

Failures in industrial machinery often manifest through early symptoms such as increased noise, vibrations, or changes in surface temperature. Detecting these signs early allows the prediction of potential failures, enabling machine suppliers and maintainers to schedule and execute maintenance and repairs on demand. This proactive approach not only prevents costly downtime but also enhances the longevity and efficiency of the machinery.

Continuous Health Status Monitoring and Failure Categorization

Continuous analysis of telemetry data enables real-time health monitoring of deployed machinery. Additionally, when failures are predicted, this data is used to categorize the type of failure, providing assistance to engineers in planning their maintenance mission. These capabilities foster increasingly effective maintenance scheduling and preparation, thereby reducing the operational costs.

Building a Knowledge Base for Optimized Inventory Planning

The systematic collection of maintenance and repair data from industrial machinery facilitates the integration of gained insights with inventory management and procurement processes. Leveraging these insights has the potential to optimize the cost-effectiveness of maintenance and repair inventory, thereby enhancing overall business efficiency.

Technical Deep Dive

System Architecture & Integration

Our predictive maintenance system for industrial rotating machines utilizes telemetry data from IoT sensors attached to each machine that are continuously collecting time-series data, including temperature, vibration, and rotation speed. This data is periodically transmitted to a central sensor data server via a gateway, consolidating preprocessing the data for analysis.

An autoencoder-based AI model processes this data to assess the health status of the machines. Should potential failure symptoms be detected, the model predicts the lead time to failure and classifies the type of failure. A key advantage of our model is that it is initially trained using only data from periods when the machine was operational, without needing initial failure data. It learns to recognize the machine’s normal operational parameters and identifies any deviations. These deviations are flagged to engineers, alerting them to potential issues.

As the system gains access to additional data over time, it uses this information to refine its predictions on failure lead times and improve its accuracy in classifying different types of failures.

The results from the AI analysis are then displayed on a dedicated dashboard for engineers. This dashboard acts as a decision support tool, providing insights that help in scheduling maintenance and repair missions effectively.

This comprehensive approach not only facilitates the early detection of potential machine failures but also enhances the classification of failure types based on historical data, significantly optimizing maintenance operations and reducing downtime in industrial settings.